182 Results for: uniVision

Enable exact search

Filter your result according to the following criteria:

Products

Added to Your Cart:

Applications

Websites

Downloads

New Products: uniVision 2.4

(465 KB)

We have summarized the most important new product features and highlights of the uniVision 2.4 image processing platform for a clearer overview.

New Products: uniVision 2.1

(437 KB)

We have summarized the most important new product features and highlights of the uniVision 2.1 image processing platform for a clearer overview.

New Products: uniVision 2.2

(436 KB)

We have summarized the most important new product features and highlights of the uniVision 2.2 image processing platform for a clearer overview.

New Products: uniVision 2.3

(440 KB)

We have summarized the most important new product features and highlights of the uniVision 2.3 image processing platform for a clearer overview.

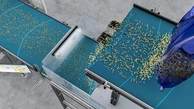

uniVision 3 Machine Vision Software Product Flyer

(1014 KB)

This document contains the product flyer for the uniVision 3 machine vision software.

HALCON Sample Scripts 1.0.1

(414 KB)

The zip file contains numerous HALCON sample scripts showing the integration into the wenglor uniVision|3 software.